- This topic is empty.

-

AuthorPosts

-

10/12/2025 at 16:05 #96928

In the fast-evolving world of digital orthodontics, precision is the key to performance. Whether it’s thermoforming, laser marking, or edge finishing, every step contributes to how comfortably and effectively clear aligners fit a patient’s teeth. Among these critical steps, aligner trimming stands as the bridge between digital design and patient comfort — where engineering precision meets clinical excellence.

To help manufacturers and dental labs achieve that balance, ConverSight introduces the HyperBrain Orthodontics Orthodontics Aligner Trimming System — an intelligent, robot-based platform designed to redefine precision, speed, and consistency in aligner edge finishing.

A New Era of Intelligent Trimming

The rise of aesthetic orthodontics has transformed the aligner market from niche to mainstream. But as demand grows, so does the pressure to improve production efficiency without sacrificing quality. Manual or semi-automatic trimming methods often lead to inconsistent edges, material waste, or long production cycles.

The HyperBrain Orthodontics Orthodontics Aligner Trimming System solves these challenges through deep integration of AI algorithms, robotic automation, and advanced motion control. It doesn’t just cut — it learns, simulates, and adapts to ensure every aligner perfectly matches the trimline for each patient case.

Understanding the HyperBrain Orthodontics Trimming Software

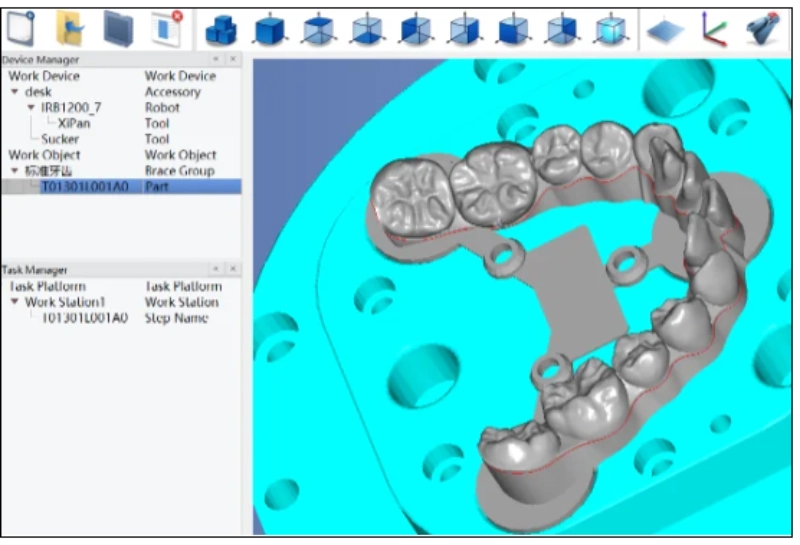

HyperBrain Orthodontics Orthodontics Software, enables intelligent planning, trajectory generation, and process optimization for aligner cutting. It combines robotic precision with AI-driven path computation to achieve high-quality consistency.

Key Functions

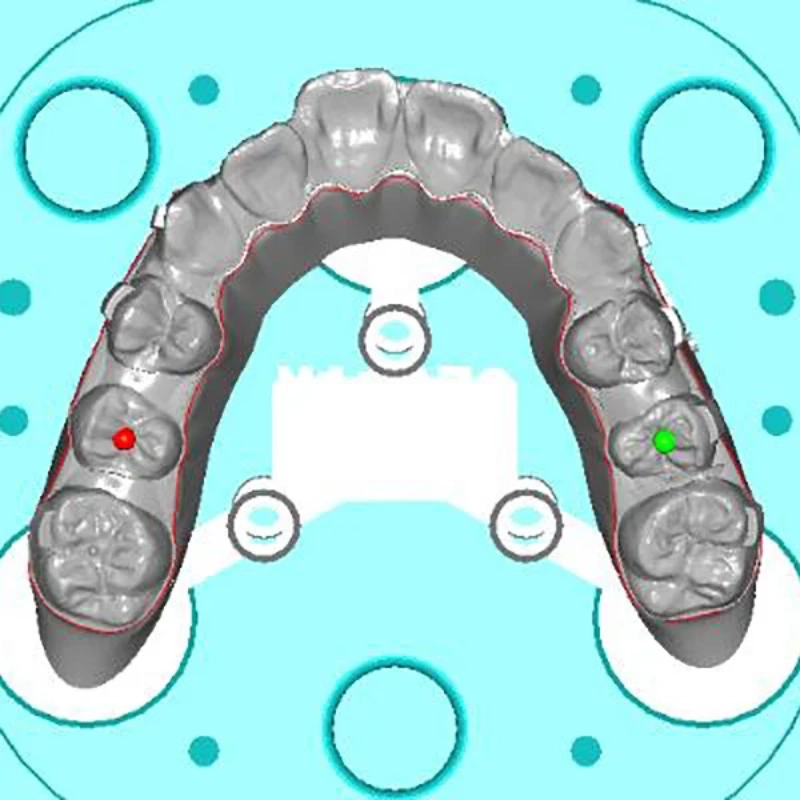

Baseplate Synthesis for Aligner Models – Seamlessly combines model base data for stable processing on the machine fixture.

Reverse and Simulate Cutting Trajectories – Allows operators to visualize and adjust the trimline before execution.

Batch Processing – Handles multiple aligner models simultaneously, boosting productivity for dental labs.

Parameter Customization – Cutting depth, speed, and edge offset can be adjusted to meet different production needs.

Automatic Robot Code Generation – Converts trimline data into executable robotic motion commands.

ICP Surface Data Acquisition – Utilizes ICP (Iterative Closest Point) algorithms to capture the aligner’s real 3D surface accurately.

Center Point Calculation – Employs minimum enclosing algorithms to determine precise aligner positioning.

Each of these functions contributes to a complete digital trimming ecosystem — from trimline design to real-time cutting.

Advantages That Set HyperBrain Orthodontics Orthodontics Apart

The HyperBrain Orthodontics Orthodontics Aligner Trimming System is more than software; it’s an integrated intelligent manufacturing solution. Let’s explore its standout advantages:

1. Rapid Deployment

HyperBrain Orthodontics Orthodontics is designed for seamless integration into existing production environments. It unifies process planning, online execution, and post-processing validation, allowing faster debugging, and system commissioning. Manufacturers can achieve full operational readiness in significantly shorter timeframes than traditional automation systems.

2. Precision Improvement

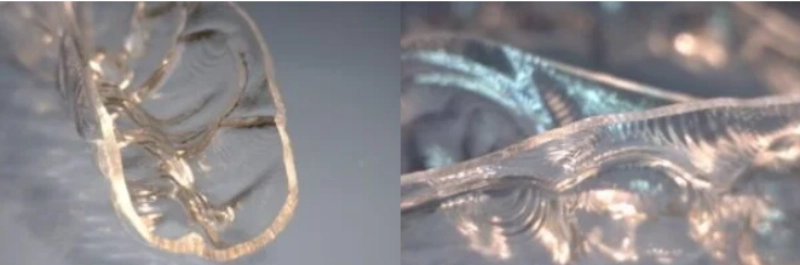

Through pre-processing visual registration and comprehensive post-processing inspection, HyperBrain Orthodontics achieves micron-level edge accuracy. The system incorporates online trajectory correction and adaptive compensation, effectively eliminating deviations caused by robot movement or material variation. This guarantees consistent, smooth cutting edges that meet orthodontic aesthetic standards.

3. Process Intelligence

Powered by a knowledge-based algorithm library, HyperBrain Orthodontics intelligently selects cutting parameters and strategies based on model geometry and material type. It ensures each aligner’s gingival margin follows the exact digital trim line, resulting in a perfect fit and superior comfort for patients.

4. Wide Compatibility

The software is compatible with industrial robots and controllers from multiple leading brands, providing flexibility to dental equipment manufacturers. Whether used in a standalone trimming station or integrated into a complete aligner production line, HyperBrain Orthodontics ensures stable communication and synchronized operation.

From Digital Design to Perfect Edge

In orthodontic manufacturing, trimming is not simply cutting — it is a precision engineering process. The edges of a clear aligner determine how it interacts with soft tissues, affecting comfort and long-term wearability.

Traditional Challenges

Manual trimming causes inconsistent edges and risk of over-cutting.

High dependency on skilled labor increases variability.

Lack of digital traceability limits quality control.

HyperBrain Orthodontics

By incorporating robotic path control, AI trajectory correction, and adaptive cutting speed adjustment, HyperBrain Orthodontics ensures that every aligner follows its digital contour precisely. The result is a consistent, polished edge — smooth to touch and visually flawless.

According to market reports from industry sources, robotic trimming systems like HyperBrain Orthodontics can achieve measurable reductions in defect rates and rework frequency, helping manufacturers maintain tighter quality control while increasing throughput.

Integration Within Automation Ecosystem

The HyperBrain Orthodontics Aligner Trimming System is an integral part of ConverSight’s intelligent dental manufacturing ecosystem, which includes:

Laser Marking Machine XJ-GL10 – Engraves permanent identification codes for traceability,with marking coordinates generated by the software.

All-in-One Automated Clear Aligner Machine – Combines forming, trimming, and marking into one seamless unit.

When combined, these modules create an end-to-end automated solution controlled by the HyperBrain Orthodontics AI Platform, providing real-time monitoring, predictive adjustments, and comprehensive data integration.

Benefits for Manufacturers and Labs

Aspect

Benefit

Efficiency

Batch processing and fast deployment reduce production time.

Precision

AI-assisted correction ensures accurate and repeatable results.

Flexibility

Adjustable parameters accommodate different aligner designs.

Scalability

Compatible with multi-robot or multi-station production lines.

Traceability

Digital workflow with data logs and trajectory records.

Manufacturers adopting HyperBrain Orthodontics report improved operational stability and scalability — vital for meeting growing market demands in aesthetic orthodontics.

Process Workflow: From Data to Delivery

Import 3D Model Data – The system reads aligner trimline data from CAD software.

Plan and Simulate Cutting Paths – Operators preview,validate and modify cutting trajectories.

Generate Robot Codes Automatically – The software outputs motion commands for robotic execution.

Perform Robotic Cutting – Robots trim aligners following the defined gingival line.

Inspect and Adjust in Real-Time – Adaptive correction compensates for any detected deviation.

Batch Data Storage – Process data are recorded for traceability and quality management.

This digital-to-physical workflow not only enhances accuracy but also establishes a continuous feedback loop for process improvement.

Future Outlook: AI and Robotics in Orthodontic Manufacturing

The success of the HyperBrain Orthodontics Aligner Trimming System represents a broader trend: the convergence of AI, robotics, and aesthetic medicine. As algorithms become more sophisticated and machine vision evolves, dental manufacturing is moving toward a fully autonomous, data-driven future.

Future developments may include:

Enhanced real-time learning systems for adaptive parameter tuning.

Integration with cloud-based design databases for remote monitoring.

Predictive maintenance powered by AI diagnostics to prevent downtime.

For dental labs and manufacturers, adopting this technology means not only improving precision but also building a competitive edge in an increasingly digital marketplace.

Conclusion

Precision is not a luxury in orthodontic manufacturing — it’s a requirement. The HyperBrain Orthodontics Aligner Trimming System from ConverSight transforms trimming from a manual task into an intelligent process, uniting robotics, data analytics, and advanced algorithms to deliver superior edge finishing for every clear aligner.

As the demand for high-quality orthodontic appliances continues to rise, manufacturers equipped with HyperBrain Orthodontics technology will lead the future of smart, scalable, and aesthetically perfect dental production.

http://www.conversighttech.com

ConverSight Technology Limited -

AuthorPosts

- You must be logged in to reply to this topic.