- This topic is empty.

-

AuthorPosts

-

28/01/2026 at 16:10 #97477

The core property of EPDM rubber foam directly determines the failure rate and service life of foam seals. Open-cell materials have interconnected microscopic air pockets, forming channels for water penetration, thus being unsuitable for outdoor sealing applications.

EPDM rubber foam features a closed-cell structure, where each internal microscopic bubble is sealed independently from the others, forming an impenetrable barrier against water. This property enables it to achieve complete waterproofing rather than mere water resistance, thereby providing long-lasting and reliable sealing for various components such as car doors and basement windows.

Ⅰ.Built-in Anti-aging Performance Ensures Decades of Outdoor Service Life for EPDM Rubber Foam

Cheap foam seals tend to become brittle and crumbly after exposure to intense sunlight in summer, mainly due to material degradation caused by ultraviolet (UV) light in sunlight. Thanks to its unique chemical composition, EPDM rubber foam has excellent UV resistance, maintaining flexibility and performance even after long-term direct sunlight without crumbling.

In addition, this material can effectively resist erosion by ozone in the air, which is one of the main factors causing cracking in ordinary rubber materials. Its excellent weather resistance ensures that seals used in scenarios such as outdoor sheds and windows will not fail due to cracking in a short period. Meanwhile, EPDM rubber foam has a wide temperature resistance range, maintaining stable performance from freezing winters to scorching summers. This is the core reason why automakers have used it as a car door sealing material for decades, and its durability can completely solve various sealing problems.

Ⅱ.Five Common Problems Permanently Solved by EPDM Rubber Foam

EPDM rubber foam integrates durability and waterproofness, with application value far exceeding ordinary weatherstripping for drafty doors and windows. It possesses excellent vibration damping, buffering and water-blocking capabilities, serving as a multi-functional material for solving dozens of common industrial and civil problems.

A single roll of material can permanently solve the following problems:

1. Vibration and noise reduction of window-type air conditioners: Laying EPDM rubber foam strips between the air conditioner body and the window sash can absorb vibrations through its dense sponge-like rubber material, significantly reducing operating noise.

2. Waterproof treatment of outdoor storage boxes: The waterproof performance of plastic deck storage boxes often fails to meet the nominal standard. Adhering adhesive-backed EPDM rubber foam strips to the inner edge of the box cover can create a tightly fitted custom gasket, completely blocking rainwater and moisture.

3. HVAC duct insulation: Exposed ducts in basements, attics and other areas are prone to energy loss. Wrapping HVAC ducts with special foam insulation tape can effectively maintain the temperature of hot and cold air flow, improving equipment operation efficiency.

4. Production of non-slip toolbox liners: Laying EPDM rubber foam liners in toolbox drawers can avoid tool collision, sliding and noise, while protecting tools from impact damage and maintaining neat placement.

5. Upgrade of vehicle seals: Seals for car trunks and truck bed caps are prone to compression deformation and failure after long-term use. As a professional-grade automotive weatherstripping material, EPDM rubber can achieve long-lasting sealing repair with factory-level quality.

Integrating sealing, vibration damping and insulation functions, EPDM rubber foam is widely applicable to scenarios such as home appliance noise reduction and property protection, serving as a highly practical industrial and civil material. There are various types of foam rubber materials on the market, and neoprene is another commonly used product.

Ⅲ.EPDM Foam vs. Neoprene: Selection Comparison for Outdoor Projects

When selecting foam rubber materials, neoprene is a common alternative. The core of selecting between the two lies in adaptability to specific scenarios rather than absolute advantages or disadvantages. EPDM rubber focuses on weather resistance, effectively resisting various climates, sunlight and water erosion; neoprene specializes in oil resistance and chemical corrosion resistance, suitable for complex medium environments.

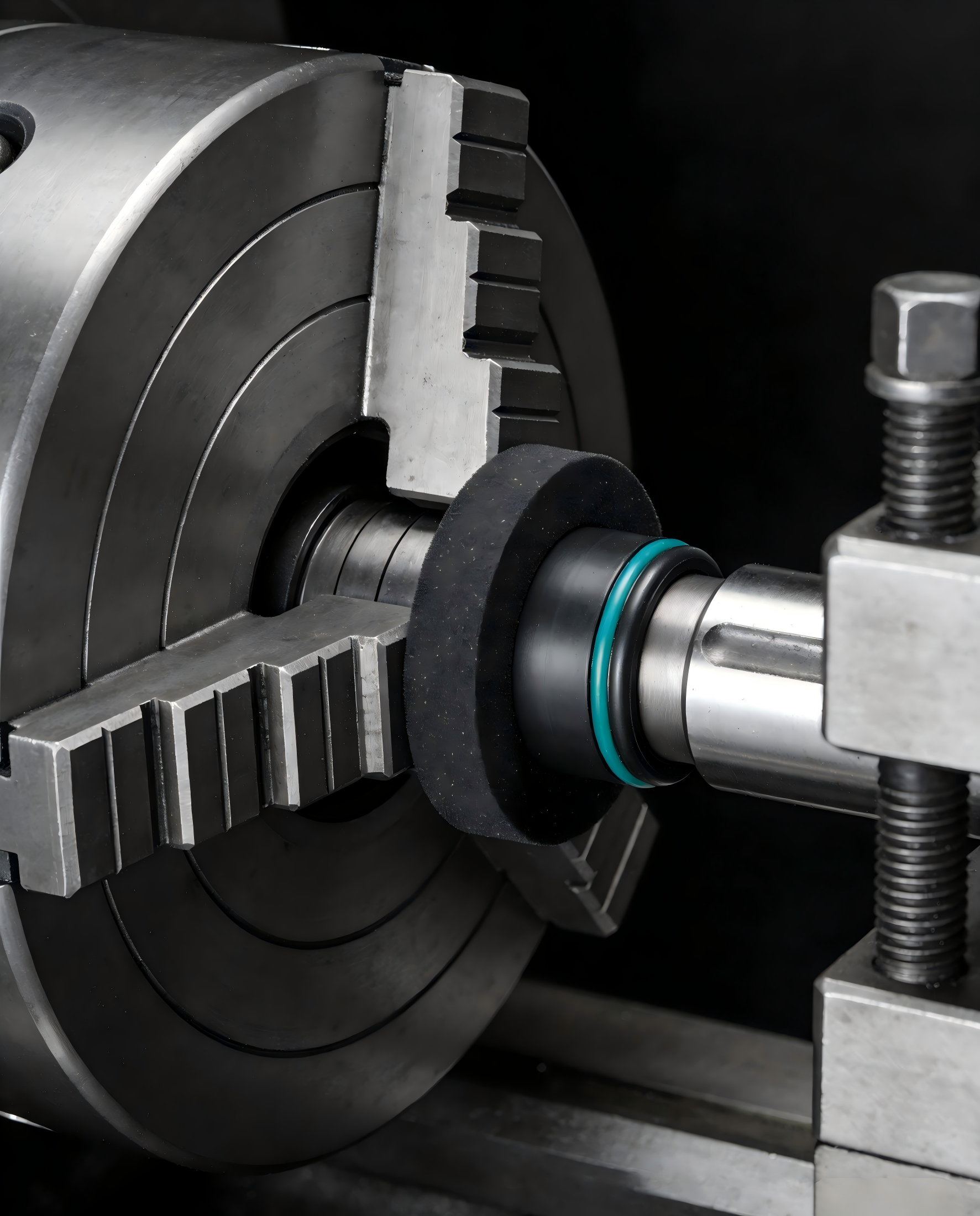

Both materials are high-quality general-purpose rubbers, but neoprene's core advantage lies in its stability in oily environments. For the production of gaskets for mechanical parts that may be exposed to oil drips, neoprene is the preferred solution as it will not degrade or swell when in contact with oil, thus being widely used in automotive engine compartments and various industrial scenarios.

However, EPDM rubber foam has significant advantages in most scenarios such as civil use, outdoor use and door/window sealing. Its irreplaceable UV and ozone resistance ensures that products such as door/window seals and automotive weatherstripping can achieve stable service for decades. The selection logic is clear: EPDM rubber is preferred for outdoor weather-resistant scenarios, and neoprene is preferred for oil-resistant scenarios.

Ⅳ.Checklist for a "Fix-It-Once" Solution

Mastering the core properties of EPDM rubber foam enables accurate distinction between low-quality, easy-to-fail foam materials and weather-resistant, durable products. The following selection guide can be referenced for subsequent project implementation:

1. Projects requiring long-term exposure to sunlight and rain: Select EPDM rubber foam.

2. Need for 100% waterproof sealing: Select closed-cell EPDM rubber foam.

3. Demand for long-term stability without short-term failure risk: Select EPDM rubber foam.

http://www.hydermanrubber.com

Hyderman Rubber & Plastic Co., Ltd. -

AuthorPosts

- You must be logged in to reply to this topic.