- This topic is empty.

-

AuthorPosts

-

15/09/2025 at 18:16 #96162

In today’s fast-paced manufacturing and logistics environment, efficiency and accuracy are key drivers of success. One essential piece of equipment that helps businesses streamline packaging and distribution is the column palletizer. Designed to stack products systematically onto pallets, a column palletizer enhances production speed, reduces labor costs, and improves workplace safety.

If you’re considering adding a column palletizer to your production line, this guide will help you understand its functions, benefits, and how to choose the right system for your business needs.

What Is a Column Palletizer?

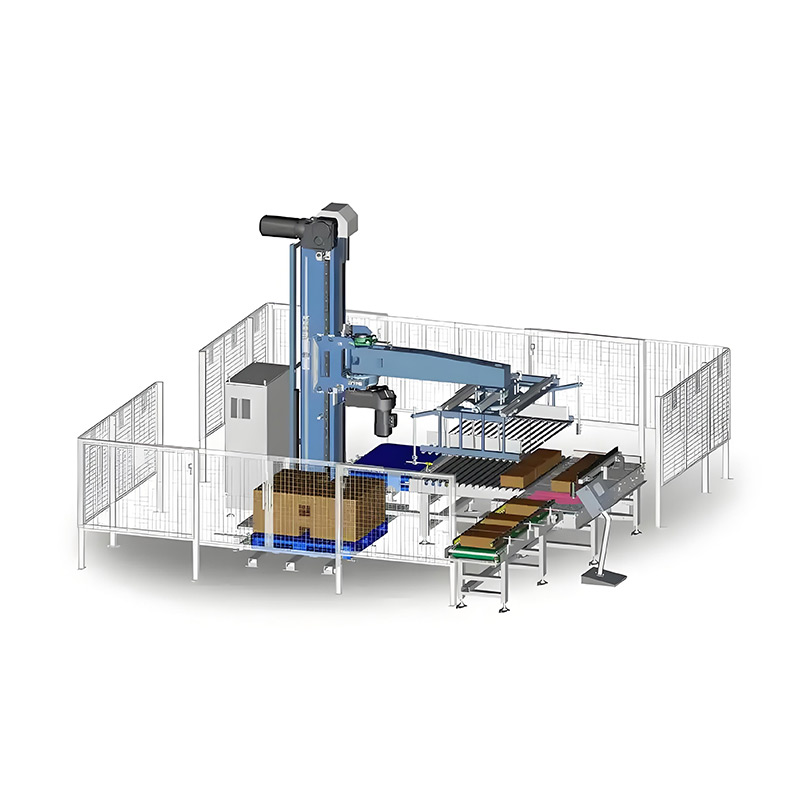

A column palletizer is a type of automated machine used to arrange packaged goods, boxes, or bags onto pallets in a uniform and stable manner. Unlike robotic palletizers, column palletizers typically move products in a vertical, column-like fashion, ensuring neat stacking and high stability.

They are widely used in industries such as food and beverage, chemicals, agriculture, and consumer goods, where consistent and efficient palletizing is required.

Key Benefits of a Column Palletizer

1. Improved Efficiency

By automating the palletizing process, column palletizers significantly increase production line speed compared to manual labor. This leads to higher throughput and more consistent operations.

2. Cost Savings

Though an upfront investment, column palletizers reduce the need for manual labor, lowering long-term operational costs. They also minimize product damage by ensuring precise stacking.

3. Enhanced Safety

Manual palletizing often involves repetitive lifting and bending, which can lead to worker fatigue and injuries. A column palletizer automates these tasks, improving workplace safety and compliance with labor regulations.

4. Space Efficiency

Column palletizers are designed to be compact, making them ideal for facilities where floor space is limited. Their vertical stacking approach allows for maximum pallet utilization.

5. Consistent Product Quality

Accurate and uniform stacking helps maintain the integrity of products during storage and transportation, reducing damage and improving customer satisfaction.

Factors to Consider When Choosing a Column Palletizer

-

Production Volume – Assess your current and future output needs. High-speed lines require machines capable of handling large volumes per hour.

-

Product Type and Packaging – Consider whether your items are cartons, bags, or bottles, as different palletizers may handle materials differently.

-

Palletizing Patterns – Check if the machine supports multiple stacking configurations to meet different customer or shipping requirements.

-

Integration with Existing Systems – Ensure compatibility with conveyors, stretch wrappers, or other packaging equipment in your production line.

-

Budget and ROI – Balance the upfront investment with long-term savings in labor and efficiency.

-

After-Sales Support – Reliable service, spare parts, and technical support are crucial for minimizing downtime.

Column Palletizer vs. Robotic Palletizer

While both systems serve the same purpose, they differ in operation and application:

-

Column Palletizer: Best for high-speed, repetitive stacking of uniform products. Cost-effective and compact.

-

Robotic Palletizer: Offers greater flexibility in handling mixed products and complex palletizing patterns, but at a higher cost.

For many businesses with standardized packaging, column palletizers provide the perfect balance of speed, efficiency, and affordability.

Why Choose Dostar Packing Equipment Co., Ltd?

As a high-tech enterprise specializing in the R&D, integration, manufacturing, sales, and service of automated packaging lines, Dostar Packing Equipment Co., Ltd delivers advanced solutions tailored to diverse industries.

-

Expertise in semi-automatic and fully automatic packaging systems.

-

A strong commitment to innovation, quality, and reliability.

-

Comprehensive after-sales service to ensure smooth operation and minimal downtime.

-

Ability to customize column palletizers based on client requirements, ensuring the best fit for each production line.

With Dostar’s proven experience, businesses can confidently integrate column palletizers to achieve higher productivity and competitiveness.

Conclusion

Choosing the right column palletizer is a strategic investment that can transform your production line. By considering your production needs, product type, and integration requirements, you can select a palletizer that maximizes efficiency and minimizes costs. With trusted partners like Dostar Packing Equipment Co., Ltd, you gain access to cutting-edge technology and reliable support, ensuring long-term success in packaging automation.

http://www.dostar-pack.com

Dostar Packing Equipment Co., Ltd -

-

AuthorPosts

- You must be logged in to reply to this topic.