- This topic is empty.

-

AuthorPosts

-

21/01/2026 at 17:35 #97378

In today’s competitive manufacturing landscape, efficiency, accuracy, and consistency are critical for packaging operations. For industries such as food, pharmaceuticals, chemicals, and consumer goods, choosing the right FFS (Form-Fill-Seal) packing machine can significantly enhance productivity while maintaining product quality. Understanding key factors in selecting the ideal machine ensures that production lines run smoothly and meet both operational and business goals.

What Is an FFS Packing Machine?

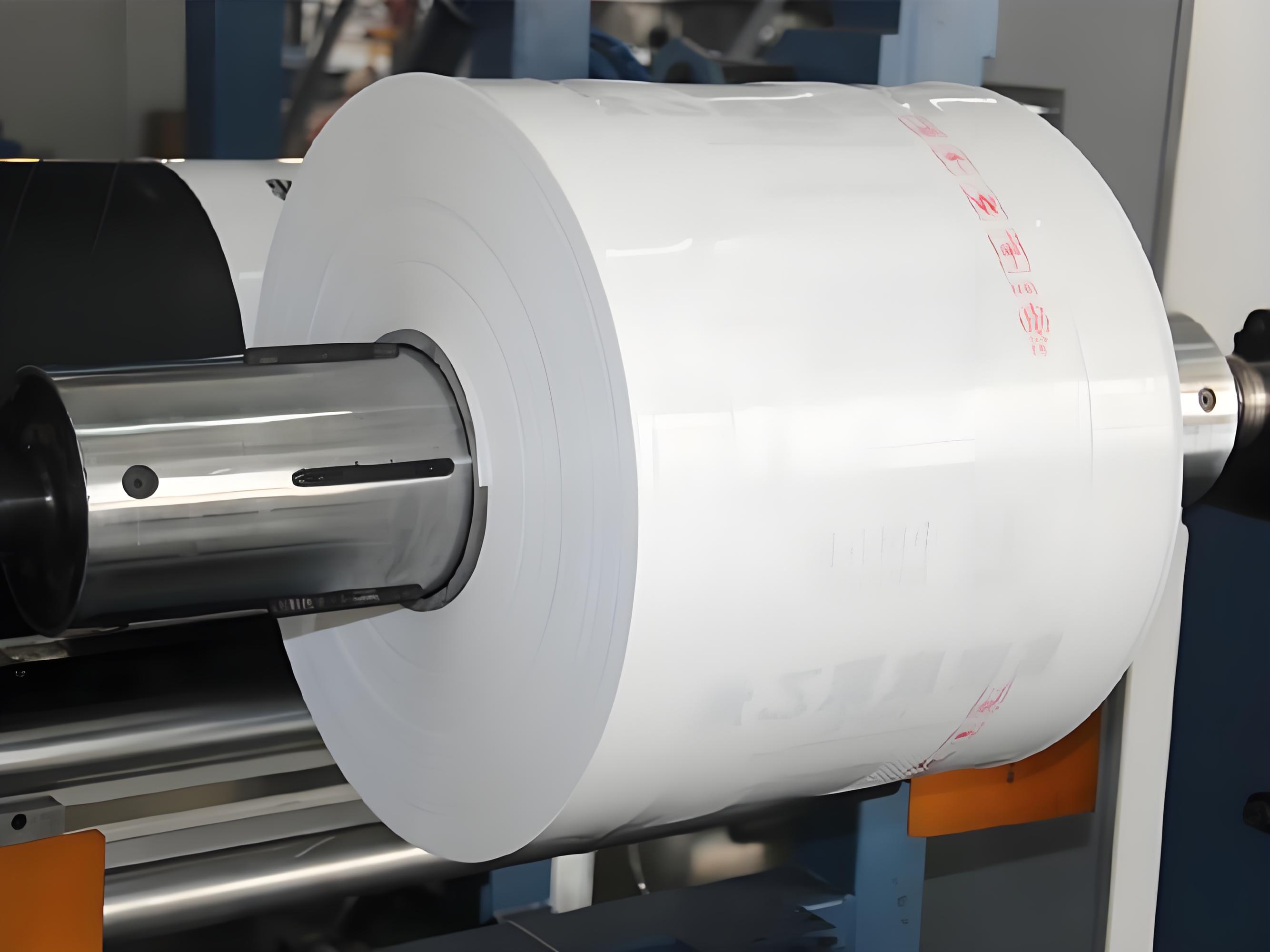

An FFS packing machine is an automated system that forms packages from flat film, fills them with product, and seals them in a single integrated process. These machines are widely used for granular, powdered, liquid, and solid products and can handle a variety of bag types, including pillow bags, gusseted bags, and quad-seal pouches. By automating the packaging process, FFS machines reduce labor costs, minimize errors, and increase production speed.

Key Factors to Consider When Choosing an FFS Packing Machine

1. Product Type and Characteristics

The first step in selecting an FFS machine is understanding the product being packaged. Different products require different handling mechanisms. For example:

-

Granular or powdered products may need auger fillers or vibratory dosing systems.

-

Liquids or sauces require precise volumetric or pump fillers.

-

Fragile items or irregularly shaped products may need specialized conveyors or cushioning mechanisms.

Choosing a machine suited to the product ensures proper filling, accurate portioning, and minimal waste.

2. Production Capacity and Speed Requirements

Production lines have varying throughput requirements depending on the scale of operations. High-speed FFS machines can produce hundreds of bags per minute, while smaller semi-automatic systems are suitable for low-to-medium volume production. Manufacturers must assess their current and projected production needs to select a machine that meets demand without overinvesting in unnecessary capacity.

3. Bag Size and Style Compatibility

FFS machines can produce a range of bag sizes and types. Factors to consider include:

-

Maximum and minimum bag width and length

-

Bag sealing type (e.g., pillow, gusseted, block-bottom)

-

Film material compatibility (plastic, laminated film, aluminum foil, etc.)

Selecting a machine that supports versatile packaging options allows businesses to adapt to market trends or launch multiple product SKUs efficiently.

4. Automation Level and Integration

FFS machines range from semi-automatic systems, which require manual loading or film threading, to fully automatic lines integrated with conveyors, filling systems, and robotic handling. Fully automated solutions reduce labor costs, enhance consistency, and streamline production. Consider integration capabilities if the packaging line needs to work with upstream and downstream processes, such as product feeders, labeling, or palletizing systems.

5. Quality, Reliability, and After-Sales Support

The durability of an FFS packing machine and the availability of maintenance support are crucial for minimizing downtime. High-quality machines feature robust frames, corrosion-resistant materials, and precise control systems. Partnering with reputable manufacturers ensures access to spare parts, technical support, and training resources, which are critical for long-term operational efficiency.

Why Dostar Packing Equipment Co., Ltd Is a Reliable Choice

Dostar Packing Equipment Co., Ltd is a high-tech enterprise specializing in the research, integration, manufacturing, sales, and service of automated packaging production lines. The company offers a range of semi-automatic and fully automatic FFS packing machines designed to meet diverse industry needs. With years of experience in packaging solutions, Dostar focuses on delivering equipment that ensures precision, efficiency, and reliability. Their expertise also includes integrating packaging systems into complete production lines, providing customers with a turnkey solution for maximum productivity.

Conclusion

Choosing the right FFS packing machine for your production line requires careful consideration of product characteristics, production capacity, bag style compatibility, automation level, and manufacturer support. Investing in a high-quality machine from a reputable company like Dostar Packing Equipment Co., Ltd ensures your packaging operations run efficiently, reduce waste, and maintain product quality. By selecting the right FFS system, businesses can enhance operational efficiency, meet market demands, and achieve sustainable growth in their industry.

http://www.dostar-pack.com

Dostar Packing Equipment Co., Ltd -

-

AuthorPosts

- You must be logged in to reply to this topic.