- This topic is empty.

-

AuthorPosts

-

08/09/2025 at 16:46 #96076

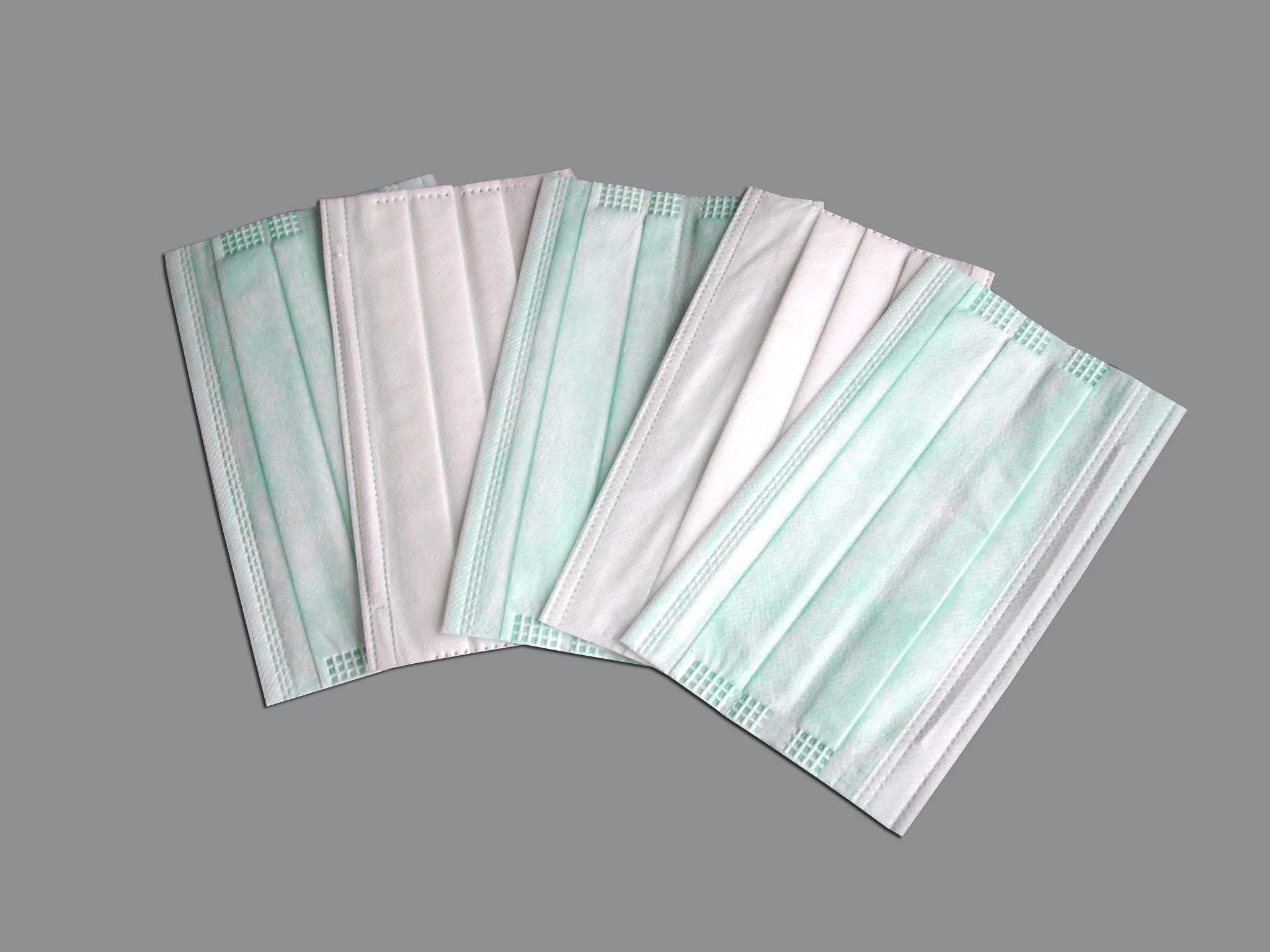

The global demand for masks has surged significantly in recent years due to heightened awareness of health, hygiene, and environmental safety. Among the critical components of mask production, mask blank body making machines play a pivotal role. These machines are designed to produce mask blank bodies with precision, efficiency, and consistency, forming the foundation for high-quality protective masks. Broadfair Automation Equipment Co., Ltd., a high-tech enterprise integrating research and development, production, and sales, has become a key player in this industry by providing advanced mask blank body making machines and comprehensive automation solutions. This article explores the top features and solutions offered by these machines, shedding light on their impact on the mask manufacturing sector.

Introduction to Mask Blank Body Making Machines

Mask blank body making machines are specialized equipment used to produce the essential blank body of masks before ear loops and other components are attached. These machines are primarily used in the production of disposable masks, including medical masks, surgical masks, and daily-use protective masks. The process involves feeding raw materials, ultrasonic welding, cutting, and shaping the blank mask body automatically. Their introduction has transformed mask production from a labor-intensive process into a highly automated, efficient, and scalable operation.

Broadfair Automation Equipment Co., Ltd. has dedicated significant resources to the innovation and advancement of these machines. Through their integrated approach of research, production, and sales, they ensure that their machines meet international standards and adapt to diverse production requirements.

High Automation and Efficiency

One of the key features of mask blank body making machines is their high degree of automation. Modern machines are equipped with advanced PLC (Programmable Logic Controller) systems and touch-screen interfaces, enabling operators to manage the production process easily. The automation reduces the need for manual intervention, minimizing errors and enhancing productivity.

Broadfair Automation Equipment Co., Ltd. offers machines that can produce thousands of mask blank bodies per hour. These machines are designed for continuous operation, with minimal downtime required for maintenance. The seamless automation ensures a consistent output that meets the growing global demand for protective masks.

Precision Engineering and Consistency

Precision is crucial in mask production, as even slight variations can compromise the mask's performance and comfort. Mask blank body making machines are equipped with ultrasonic welding technology, ensuring accurate bonding of materials without the need for glue or additional chemicals. This results in clean, durable, and reliable mask blank bodies.

Broadfair Automation's machines are engineered with precision cutting tools and intelligent alignment systems that guarantee uniform shapes and sizes. The consistency achieved by these machines reduces waste and ensures that subsequent production steps, such as ear loop welding and packaging, proceed smoothly.

Versatile Production Capabilities

Mask blank body making machines from Broadfair Automation Equipment Co., Ltd. are designed to accommodate various mask types and sizes. Whether for three-ply medical masks, N95 masks, or customized designs, these machines can be adjusted to meet specific production requirements.

Their modular design allows for quick changeovers between different mask types, making them suitable for manufacturers catering to multiple markets. This versatility is particularly valuable in a rapidly changing market where demand for different mask types can shift quickly.

User-Friendly Operation and Safety Features

Ease of use is a critical factor for manufacturers when choosing mask blank body making machines. Broadfair Automation's machines feature intuitive controls, automated material feeding systems, and real-time monitoring, making them accessible even to operators with minimal technical training.

In addition to user-friendly operation, these machines are equipped with comprehensive safety features, including emergency stop buttons, fault alarms, and protective enclosures. These measures ensure operator safety and protect the equipment from damage during operation.

High-Quality Materials and Durability

Durability is a key consideration for mask production equipment, as manufacturers aim for long-term operation with minimal downtime. Broadfair Automation Equipment Co., Ltd. uses high-quality materials and components in their mask blank body making machines, ensuring robust performance under continuous operation.

The machines are designed for easy maintenance, with replaceable components and accessible parts. This reduces maintenance costs and prolongs the lifespan of the equipment, providing manufacturers with a reliable and cost-effective solution.

Energy Efficiency and Environmental Considerations

Sustainability is becoming increasingly important in the manufacturing sector. Mask blank body making machines from Broadfair Automation are designed to minimize energy consumption while maintaining high production output. Their energy-efficient components and optimized processes help reduce the carbon footprint of mask production.

Additionally, the use of ultrasonic welding eliminates the need for adhesives or solvents, contributing to a cleaner and more environmentally friendly manufacturing process. This aligns with global efforts to promote sustainable production practices.

Customization and Integration Solutions

Every mask manufacturer has unique requirements based on their target market, production scale, and product specifications. Broadfair Automation Equipment Co., Ltd. offers customization services to tailor their mask blank body making machines to specific needs. From adjusting machine dimensions to integrating additional modules, they work closely with clients to deliver bespoke solutions.

Moreover, these machines can be seamlessly integrated into existing production lines, ensuring a smooth transition for manufacturers upgrading their facilities. Broadfair's expertise in automation enables them to provide end-to-end solutions, including installation, training, and technical support.

After-Sales Support and Global Reach

A critical aspect of choosing mask blank body making machines is the availability of reliable after-sales support. Broadfair Automation Equipment Co., Ltd. provides comprehensive after-sales services, including remote technical assistance, spare parts supply, and on-site maintenance.

Their global network ensures timely support for international clients, making them a trusted partner for mask manufacturers worldwide. This commitment to customer satisfaction has earned them a strong reputation in the industry.

Conclusion

Mask blank body making machines are essential for efficient and reliable mask production. With features such as high automation, precision engineering, versatility, and energy efficiency, these machines have revolutionized the industry. Broadfair Automation Equipment Co., Ltd., with its expertise in research, production, and sales, offers comprehensive solutions that cater to the diverse needs of global mask manufacturers.

By investing in advanced mask blank body making machines, manufacturers can ensure consistent production quality, reduce operational costs, and meet the ever-growing demand for protective masks. As the industry continues to evolve, companies like Broadfair will play a crucial role in shaping the future of mask manufacturing.

Mask Blank Body Making Machine: Technical Features and Practical Benefits

http://www.broadfairmachine.com

Broadfair Automation Equipment Co., Ltd. -

AuthorPosts

- You must be logged in to reply to this topic.