- This topic is empty.

-

AuthorPosts

-

09/02/2026 at 11:32 #97638

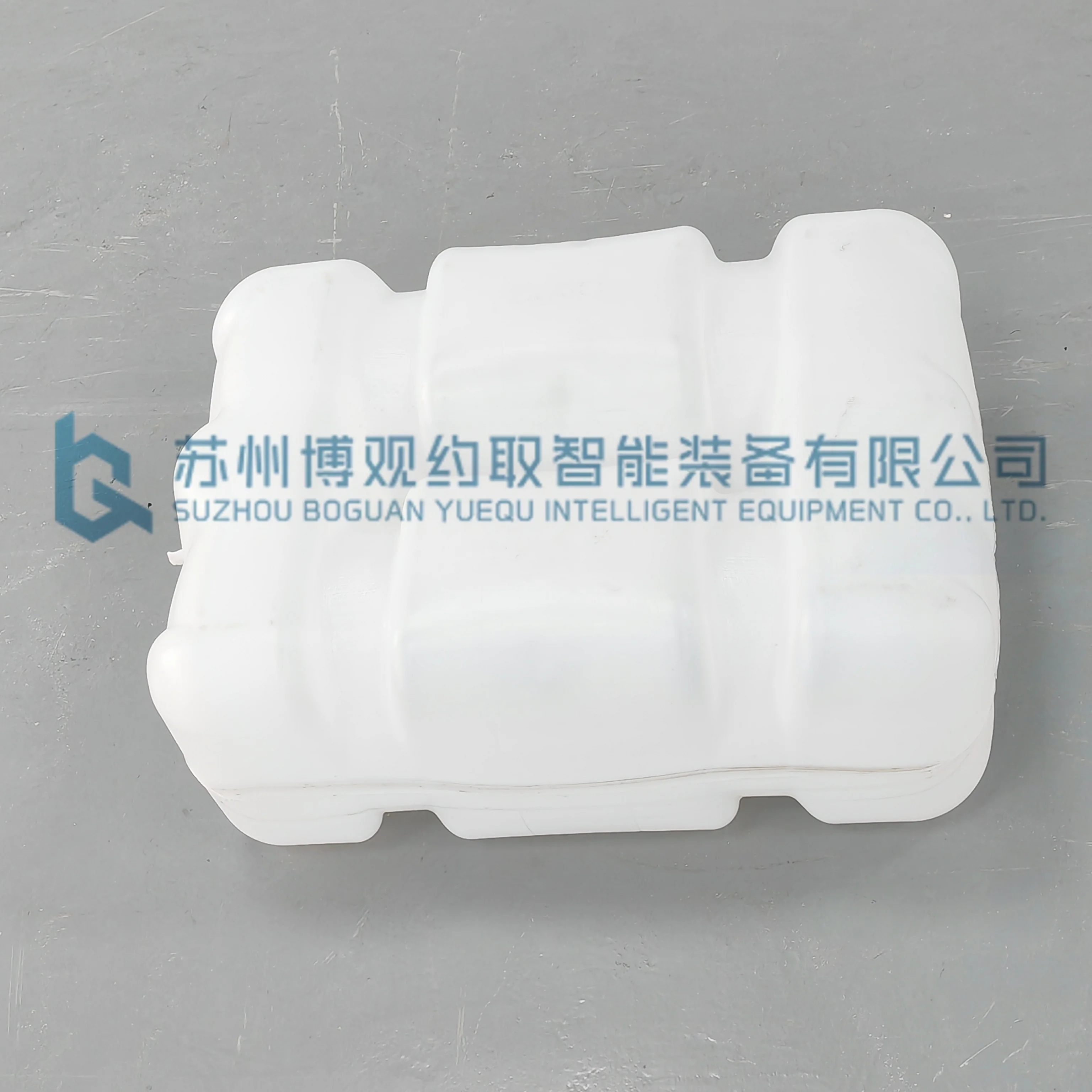

As modern construction and infrastructure projects continue to evolve, engineers and contractors are increasingly turning to advanced materials that offer durability, efficiency, and cost control. One such innovation gaining attention is the MDPE integrated polymer composite load-reducing component. Designed to improve load distribution and structural performance, this component plays a critical role in contemporary formwork, foundation, and structural support systems.

This article provides a practical introduction to what an MDPE integrated polymer composite load-reducing component is, how it works, and why it is becoming an essential solution in today’s construction and industrial engineering projects.

Understanding MDPE Integrated Polymer Composite Components

MDPE (Medium-Density Polyethylene) is a thermoplastic polymer known for its excellent balance of strength, flexibility, and chemical resistance. When MDPE is combined with reinforced polymer composites and engineered into an integrated load-reducing component, the result is a high-performance structural element designed to manage and distribute loads more effectively.

Unlike traditional metal or rigid plastic components, MDPE composite load-reducing parts are engineered to:

-

Absorb and redistribute pressure

-

Reduce localized stress concentrations

-

Improve overall structural stability

Their integrated design allows them to function as a single, unified unit within a construction or formwork system.

How Does a Load-Reducing Component Work?

In construction and formwork systems, excessive point loads can lead to:

-

Structural deformation

-

Premature material fatigue

-

Safety risks on site

An MDPE integrated polymer composite load-reducing component works by spreading applied forces across a wider surface area. This load dispersion minimizes stress on individual elements such as formwork panels, supports, and connection points.

Thanks to MDPE’s natural flexibility and resilience, the component can absorb dynamic loads, vibration, and minor structural movement without cracking or permanent deformation—something rigid materials often struggle to achieve.

Key Advantages of MDPE Polymer Composite Load-Reducing Components

1. Excellent Load Distribution

The primary benefit of these components is their ability to reduce concentrated loads. This helps protect supporting structures and extends the service life of construction systems.

2. High Durability and Impact Resistance

MDPE polymer composites offer strong resistance to impact, abrasion, and repeated loading cycles, making them ideal for demanding construction environments.

3. Lightweight Yet Strong

Compared to metal alternatives, MDPE integrated components are significantly lighter, which simplifies handling, transportation, and on-site installation—reducing labor time and costs.

4. Corrosion and Chemical Resistance

MDPE is inherently resistant to moisture, chemicals, and corrosion, allowing the component to perform reliably in outdoor, underground, and high-humidity conditions.

5. Cost-Effective Long-Term Performance

Lower maintenance requirements and longer service life make MDPE composite load-reducing components a cost-effective solution over the entire project lifecycle.

Common Applications in Construction and Engineering

MDPE integrated polymer composite load-reducing components are widely used in:

-

Formwork and shuttering systems

-

Foundation and slab support structures

-

Temporary construction supports

-

Industrial equipment bases

-

Infrastructure and civil engineering projects

Their adaptability makes them suitable for both temporary and permanent structural applications.

Role of Integrated Design in Modern Formwork Systems

Modern formwork systems demand precision, safety, and efficiency. Integrated polymer composite components help achieve these goals by reducing stress on formwork panels and connection points, improving dimensional stability, and enhancing overall system reliability.

By incorporating load-reducing components directly into the system design, engineers can optimize structural performance while minimizing material usage and on-site adjustments.

About SUZHOU BOGUAN YUEOU INTELLIGENT EQUIPMENT CO., LTD

SUZHOU BOGUAN YUEOU INTELLIGENT EQUIPMENT CO., LTD specializes in the research, development, and manufacturing of advanced formwork systems and intelligent construction equipment. With a strong focus on innovation and practical engineering solutions, the company provides high-quality products designed to improve construction efficiency, safety, and sustainability.

By combining modern materials science with intelligent manufacturing processes, the company develops solutions such as polymer composite components that meet the evolving demands of global construction projects.

Learn more about the company and its capabilities here:

https://www.szformwork.com/About-Us.htmlWhy MDPE Composite Load-Reducing Components Are the Future

As the construction industry continues to prioritize efficiency, safety, and sustainability, materials like MDPE polymer composites are becoming increasingly important. Their ability to reduce structural stress, withstand harsh environments, and lower overall project costs makes them a smart choice for forward-thinking engineers and contractors.

Conclusion

An MDPE integrated polymer composite load-reducing component is more than just a structural accessory—it is a practical engineering solution designed to improve load management, durability, and efficiency in modern construction systems.

With their lightweight design, corrosion resistance, and excellent load-distribution capabilities, these components are redefining how formwork and structural support systems are built. Supported by experienced manufacturers like SUZHOU BOGUAN YUEOU INTELLIGENT EQUIPMENT CO., LTD, MDPE composite solutions are well-positioned to play a key role in the future of intelligent construction.

Design and Application of Waffle Slab Formwork for Modern Structural Projects

http://www.szformwork.com

SUZHOU BOGUAN YUEOU INTELLIGENT EOUIPMENT CO., LTD -

-

AuthorPosts

- You must be logged in to reply to this topic.